Over the last couple of years, the TRS Sprayers & Equipment team have been working to design and build a fully electrically powered commercial orchard sprayer alongside our fan partner, Weber in Germany. The close collaboration with Weber has allowed the successful development of the sprayer with the simplicity, durability, proven spray performance and low operating power requirement. Nelson, NZ based engineers, Trinder Engineering have been an integral part in the development of the structural components along with the assembly of the sprayer, working alongside us to make changes where necessary to ensure the durability of the machine.

This was a prototype sprayer designed specifically to suit the cherry orchard requirements by Euan White & Mike Casey at Forest Lodge Orchard in Mt Pisa, New Zealand. We asked Euan & Mike for some feedback; this is what they had to say:

Electric Cherries at Forest Lodge.

At Forest Lodge Orchard we operate the fully electric Monarch tractor and needed a sprayer built to allow us to electrify the entire orchard process. The Electric Orchard sprayer, by TRS Sprayers & Equipment, seamlessly connects to the tractor, and using the battery from the tractor, powers the sprayer pumps and the fans. The TRS Sprayer gives us the method, via electric drive, to deliver the extended runtime we need (8+ hours) to complete a spray of our entire orchard. We calculated when using a traditional PTO driven sprayer, it would not give us the runtime we need as the power requirement would be too high for a meaningful runtime.

Using the sprayer has given us the capability to apply agrichemicals to our crop in the most efficient and effective way possible.

“We are always striving for efficiency and the TRS sprayer ticks this box.”

Comparing to a traditional PTO driven sprayer vs E-drive efficiencies – the deciding factor.

In our orchard, we typically use a water rate of 1500 litres per hectare while our canopy is dense (during late spring and summer), and 750-1000LpH when the canopy is either developing or thinning (during autumn and early spring).

Our normal travel speed while spraying is 5km/h. The rate controller allows for a variation of speeds and ensures the application rates are maintained, the four fans can be independently controlled on / off and fan speeds are also individually adjustable from a fan speed control mounted on the tractor. The benefits here, is this allows them to spray in windy conditions as well as energy savings from targeted spraying such as thinning.

Our calculations indicate that an equivalent traditional PTO- driven sprayer would have a runtime of around 2.5 hours given the battery size of the Monarch tractor. With our new sprayer we have a runtime of 8+ hours.

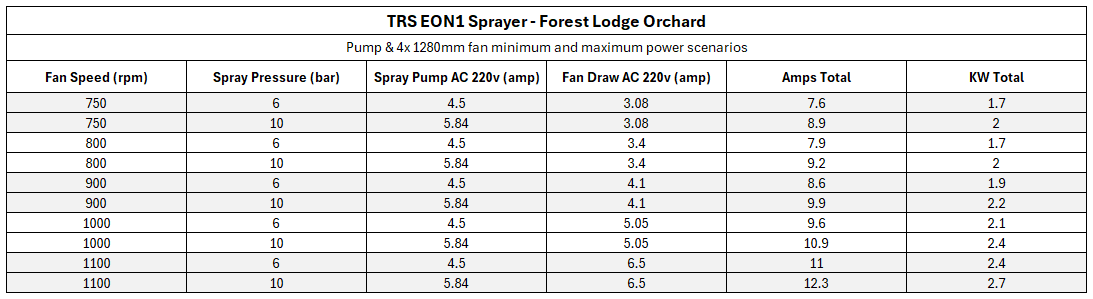

The sprayer pump uses 1.3kW when running at 10bar operating pressure, and the fans use 0.7kW from dormancy through to post flowering and up to 1.2 kw at Harvest.

The running costs for the TRS EON1 Sprayer are very impressive.

As it runs entirely from the battery power of the tractor, there are very few moving parts. In the TRS Sprayers first 6 months of operational use, we have had no problems and other than preventative maintenance (greasing bearings etc).

Working together to electrify another key component of the orchard.

The E-Sprayer concept was first designed 3 years ago, and with the assistance of Product Development Manager, Greg Small, and the rest of the team at TRS Wholesale (manufacturers of TRS Sprayers & Equipment), who researched and developed the sprayer, and making improvements alongside our feedback, we have got to where we are with the latest version today.

Greg & the TRS Wholesale team are vastly experienced in sprayers, but the concept of a fully electrically driven sprayer was new ground for everyone.

A careful and meticulous approach saw that our requirements were met regarding spray rates and air movement, sprayer set up and special considerations to lower power input, allows us to conserve energy and optimise the tractor battery run time in a very efficient manner. The communication from TRS Wholesale was excellent, and updates on progress were provided regularly.

The TRS Sprayer with the Weber Tangential Fans are well suited to our UFO style growing structure, these are commonly hydraulically driven, the sprayer was initially supplied without fans while the team at TRS Wholesale worked with fan supplier Weber to develop a robust, safe 48v DC drive system that offers independent variable speed drive system and integration to the Monarch Electric tractor.

Although through initial research around the spray and fan performance was expected to be good, the power requirement, spray coverage and operating noise levels has exceeded our expectations.

Efficient and effective – the finished product.

The final version of the TRS EON1 Sprayer with updates and new fans, was delivered to us in October 2023 and has completed our fleet of equipment that we need to produce cherries of the highest quality. The sprayer delivers the products efficiently, effectively and is very easy to operate.

Our orchard hosts several thousand visitors per year and each one gets a viewing and explanation of the sprayer, with demonstrations available on request.

We are proud to be working alongside the TRS Sprayers team and have their Electric Sprayer in our fleet, we see it as a critical part of our operation to ensuring a high level of crop protection and producing high-quality fruit. At Forest Lodge Orchard, we see the total electrification of horticulture as not only achievable, but to reduce (or eliminate entirely) on-farm emissions which is a win for everyone.

See our full story https://www.forestlodge.nz/

Forest Lodge Orchard 8- month test data:

Covered 105 ha. Applied 100,000 litres.

Run for 100 hrs. Sprayed 470 km.